Mayfran offers more - All from one source

At Mayfran, you will always find a solution for coolant filtration, as well as chip and scrap handling applications.

- From conceptual design through to planning, installation & commissioning, we provide our services worldwide.

- Comprehensive and individually tailored service concepts also complement our offers.

- All from a one source, is not just an a strap line for us, we constantly strive to offer our customers new and additional productivity advantages from within the Mayfran portfolio.

- We understand how important it is for our customers to be able to rely on our products, to ensure efficiency and reliability of its own machinery.

- There are good reasons why Mayfran is a leading supplier in many key manufacturing sectors.

- Whether it’s the automotive or aerospace world, within the engineering and recycling industries.

We are at your service!

Mayfran offers more - All from one source

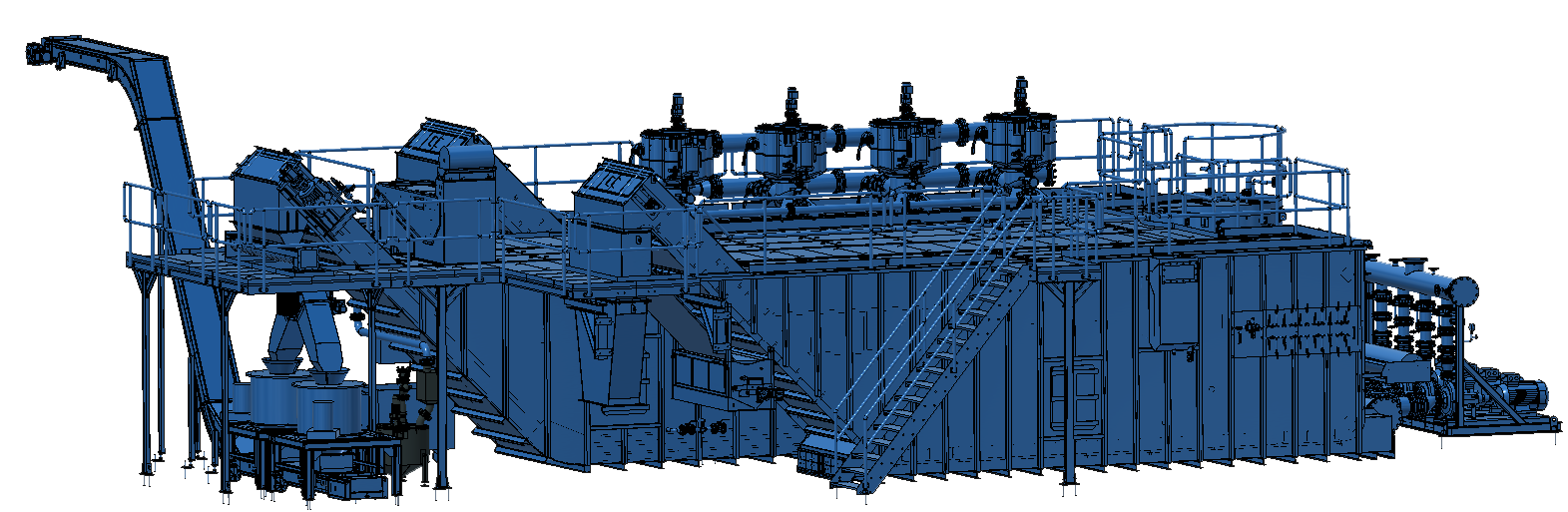

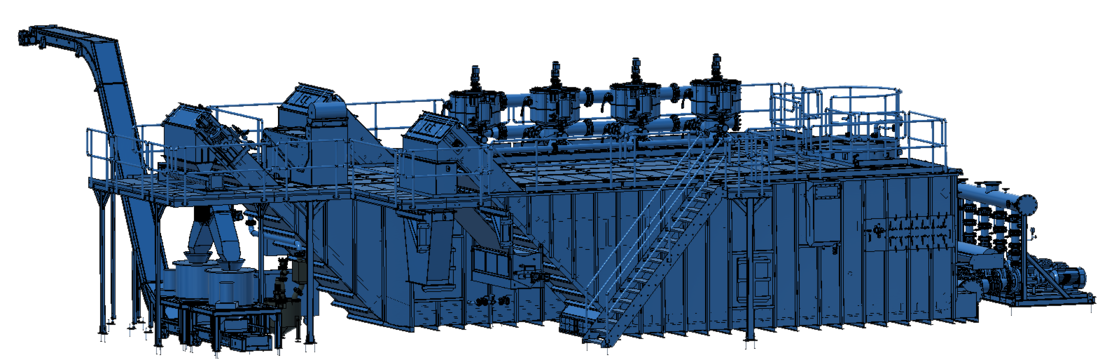

central filtration

Mayfran designs and builds complete, custom filtration systems for central processing of coolant and chips for multiple machine tools. These systems can process the desired flow rates with one or more modules. A wide range of filtration technologies, including gravity, pressure, vacuum, and precoat filters, allows us to find the best solution for your needs from 100 l/min to 20.000 l/min.

Decades of experience in the design and implementation of central filter systems, sound resources in project management and engineering and a wide range of filter technologies make Mayfran the safe choice for your coolant cleaning.

In addition, we can incorporate the unique Viavent surface-mounted return pump system and chip handling and processing solutions to provide an optimized chip and coolant processing system.

RECYCLING INDUSTRY SOLUTIONS

Mayfran produces innovative and efficient material handling equipment for the recycling industry.

Our steel plate belt conveyors are used in the following industries:

- steel and metal recycling

- scrap processing

- press shops

- punching shops

- waste processing

- waste incineration plants

- ashes disposal

- recycling plants

- foundries

- waste wood recycling

With our conveyor technology we transport

- cast iron and steel chips

- press and punching scrap

- chip briquettes

- scrap metal packages

- electronic scrap

- cast and forged parts

- wood waste such as wood chips

- waste and recycling materials

Our solutions are characterized by exceptional conveying capacities, wear resistance and robustness as well as availability requirements and are designed for various applications.

For more complex requirements, we develop complete conveyor systems, such as sheet metal scrap disposal systems, which are used to dispose of entire production plants by means of container changing systems by combining various individual conveyors and movable chutes.

With decades of experience, Mayfran designs systems to meet solution-oriented and industry-specific requirements.

Highlights

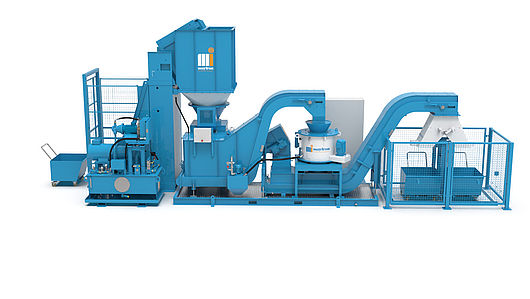

ConSep 2000 25th anniversary

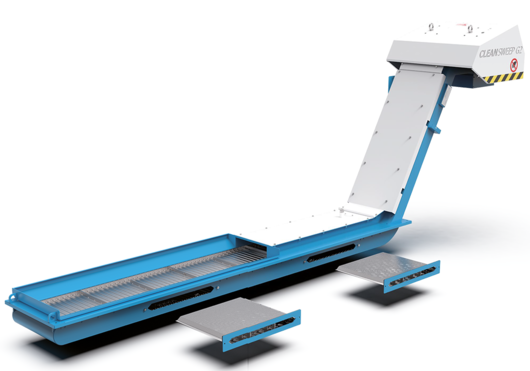

Cleanweep G2

The answer to the multi-tasking machine tool future

Secure Chip Removal at Räthische Bahn AG Switzerland